Waste Management

In accordance with the ISO 14001 standard, LITE-ON has set up a dedicated unit to effectively track the source and output of waste, follow the guidelines of maximizing resource use and minimizing waste output, and promote green product design and waste management measures. LITEON sets waste reduction targets each year, minimizes the amount of waste produced during production, increases the life cycle of each raw material, and enhances the recycling and reuse of sustainable resources to achieve the waste reduction target. When disposing of waste, select qualified waste disposal units that can effectively process waste for treatment, audit the treatment units through on-site or forms, etc., confirm that the waste treatment units are properly disposed of, and ensure that the waste produced will not have a significant impact on the surrounding environment.

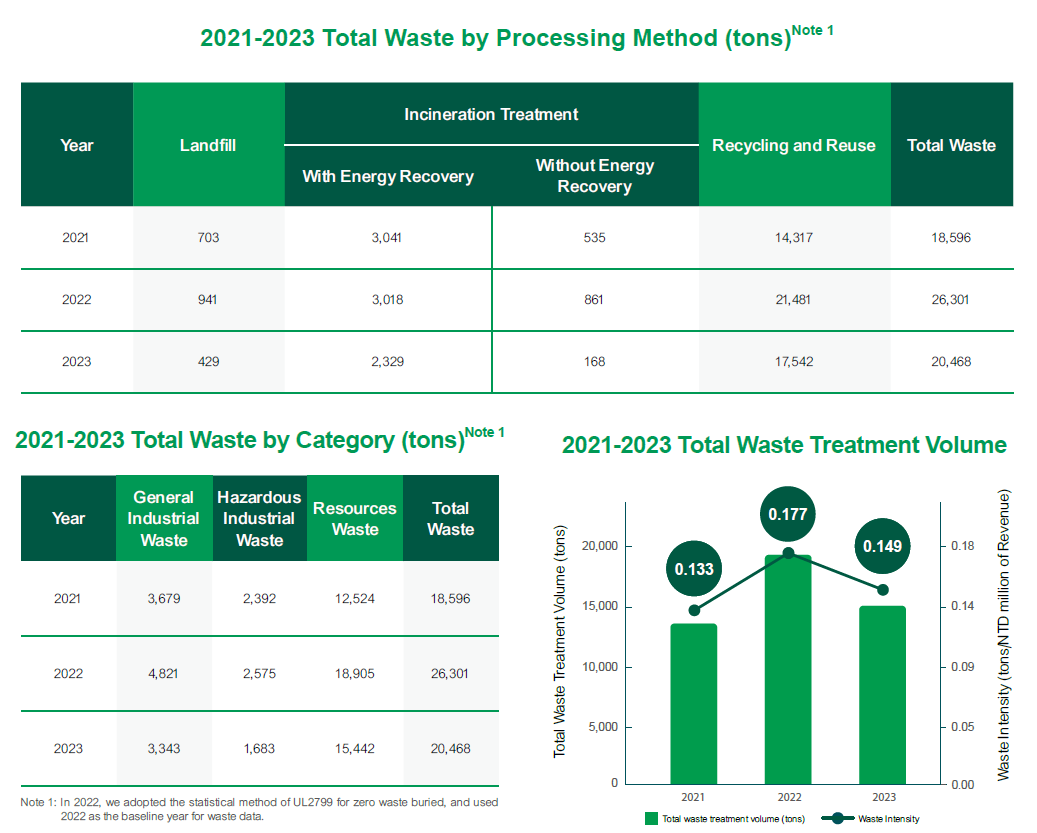

LITEON defines waste as materials that no longer enter the manufacturing process after operation or production, and the amount of waste discharged is calculated based on the total amount of waste that is weighed by the waste disposal unit at the time of leaving the factory. The general treatment methods of general industrial waste include landfill treatment and incineration treatment (excluding or including energy recovery), and hazardous industrial waste treatment methods include landfill treatment, incineration treatment (excluding or including energy recovery), and resource reuse. The total waste in 2023 is 20,468 metric tons, and the waste intensity is 0.149 metric tons/NT$million in revenue. LITEON will continue to improve its waste management and continue to move towards the goal of reducing waste by 6% by 2025 compared to 2022.

To further implement LITEON's waste recycling philosophy, we introduced UL 2799 Zero Waste to Landfill statistic at our sites. We achieved the platinum level in the Dongguan factory, and also introduced this statistical method to other factories. Therefore, we can calculate waste statistics on the site more accurately. We not only increase the waste conversion rate and reduce the waste output, but also reduce the amount of resource recovery and improve the resource recovery rate. When carrying out removal, we also ensure that the waste disposal method of disposal service providers complies with local regulations.

LITEON's waste recycling solutions include reusing or reducing packaging materials, plastics, cardboard and cartons, recycling alcohol and selecting pallet to reduce waste generation. In the selection of pallets, LITEON coordinates with upstream suppliers to use more durable pallets. Using the Guangzhou plant as an example: more durable plastic pallets are used to improve the utilization rate of pallets. For loading, the cartons were changed to plastic cartons to improve the recycling rate. In terms of packaging, by reducing the use of cardboard, LITEON improved the utilization rate of cardboard and reduced procurement by about 20% a year. In terms of waste disposal, in addition to hiring qualified waste collection and disposal service providers to handle incineration and processing for reuse, LITEON adopts a responsible production philosophy and conducts regular supplier audits to ensure waste is properly handled.

LITEON defines waste as materials after operation or production that will no longer enter the process stage. The total amount of waste discharged is calculated as the total weight of waste weighed by the waste treatment unit at the time of leaving the factory. Waste treatment methods include landfill, incineration (including/not including energy recovery), and recycling for reuse of resources. Due to the introduction of the concept of zero waste to landfill, the statistical method is inconsistent with the base year data, so the waste target has been reset to reduce waste intensity by 2% per year with 2022 as the base year. The total waste volume in 2022 was 26,301 tons the waste intensity was 0.177 tons / NTD million of revenue in 2022. LITEON will continue to improve waste management and work towards the goal of reducing absolute waste intensity by 6% by 2025 as compared to 2022.

Waste Reduction and Recycle

To further implement the concept of waste recycling, LITEON has introduced the statistical method of UL 2799 zero waste to landfill to the factory. Auditing the stock of all types of waste in the factory and reducing the output of waste, we first achieved the platinum level target of the UL 2799 verification in the Dongguan factory in 2022, and at the same time, we also expanded this statistical logic to other factories. In 2023, the Changzhou site, Guangzhou site, and Shijie site obtained the platinum level of the UL 2799 verification. Through this method, we can calculate the waste of the plant more accurately, and at the same time, we can improve the waste conversion rate, and reduce incineration with or without energy generation or landfill waste. By increasing the recycling rate of LITEON waste, switching products and transportation materials to newer technologies or materials, and investing in them. We also ensure that the waste disposed of by the disposers complies with local regulations.

In the waste recycling plan, we first check the source and flow direction of the waste, analyze the waste that does not reach 100% according to the UL 2799 conversion rate and the causes, find out the difficulties and bottlenecks of reuse, analyze whether it can be reused or recycled in the factory, seek the assistance of external recycling units, and find suitable and qualified manufacturers for recycling waste materials when cooperating with external units, to effectively convert hazardous business waste and improve waste efficiency. For example, we identified opportunities on the recyclabilities of containers and their impact on the processes. We decided to use recyclable containers instead of one-time-use containers. To reduce the environmental impact by reusing waste that can only be burned or buried in the waste disposal area, LITEON not only entrusts qualified removal processors to incinerate or reuse the waste but also conducts regular audits by disposal operators to ensure proper disposal with the concept of a responsible producer.